OSG Plastics – Comprehensive Solutions for the Plastics Industry

At OSG Plastics, our goal is to support you and facilitate all phases of production in the plastics industry, from transportation to storage and process optimization. We specialize in providing comprehensive solutions that adapt to the specific needs of each project, ensuring efficient and safe handling of the product at every stage of production.

Main features of OSG Plastics

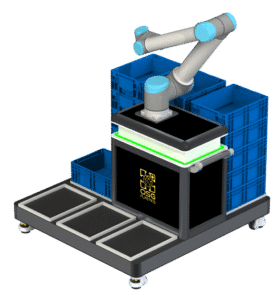

Robot conveyor – FCR model

Flat conveyor – FC model

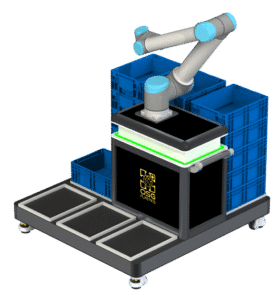

Designed to integrate robotics into production processes, this flat conveyor features safety fencing to allow safe interaction between machines and operators. Its configuration is adaptable, allowing for a perfect fit to the customer’s space and needs.

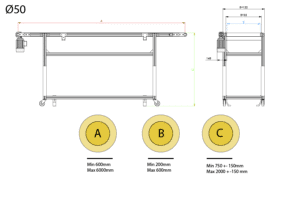

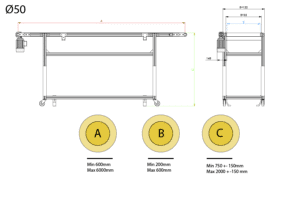

This versatile conveyor facilitates the handling of products at different stages of production. Available in configurations that adjust to the volume and load of the product, its modular design allows for simple and effective integration into any workspace.

Diverter Injector – Model DC

Transporters of Inflection – Models IC and IIC

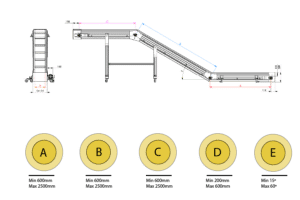

Specifically designed to be placed at the output of injectors, this equipment allows for precise handling of parts, even in areas with limited space. Its ability to operate in both directions automates the selection of parts, efficiently discarding defective ones.

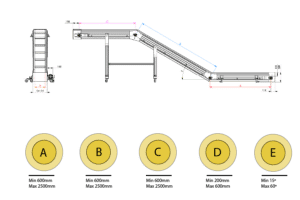

From simple to double transport with adjustable bends, these conveyors are ideal for moving products between different levels of the production line. Their design allows for height adjustments to meet the specific needs of each operation.

Elevator – Model EV

Buffer systems and thermal insulation covers

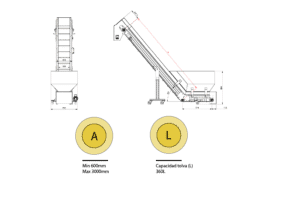

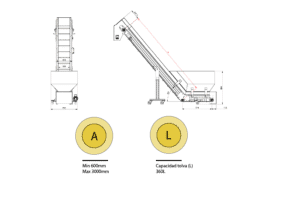

This elevator acts as a buffer within the production line, accumulating products to ensure a continuous and uninterrupted flow. It is designed to minimize the required space while maximizing efficiency in handling products at different heights.

Innovations such as the OLIVE vertical buffer system and thermal insulation covers provide practical solutions for product handling and energy optimization. These systems enhance operational efficiency and reduce downtime and energy costs.

Designed to integrate robotics into production processes, this flat conveyor features safety fencing to allow safe interaction between machines and operators. Its configuration is adaptable, allowing for a perfect fit to the customer’s space and needs.

This versatile conveyor facilitates the handling of products at different stages of production. Available in configurations that adjust to the volume and load of the product, its modular design allows for simple and effective integration into any workspace.

Specifically designed to be placed at the exit of injectors, this equipment allows for precise handling of parts, even in areas with limited space. Its ability to operate in both directions automates the selection of parts, efficiently discarding defective ones.

From simple to double transport with adjustable bends, these conveyors are ideal for moving products between different levels of the production line. Their design allows for height adjustments to meet the specific needs of each operation.

This elevator acts as a buffer within the production line, accumulating products to ensure a continuous and uninterrupted flow. It is designed to minimize the required space while maximizing efficiency in handling products at different heights.

Innovations such as the OLIVE vertical buffer system and thermal insulation covers provide practical solutions for product handling and energy optimization. These systems enhance operational efficiency and reduce downtime and energy costs.

Commitment to innovation and quality

At OSG Plastics, we are committed to continuous improvement and innovation in all our solutions. Our wide range of equipment is manufactured to the highest quality standards, ensuring that each product not only meets but exceeds our customers’ expectations in terms of performance and reliability.

Discover how OSG Plastics solutions can transform your production process and elevate your plant’s efficiency. Contact us today for more information or to schedule a demonstration of our products.