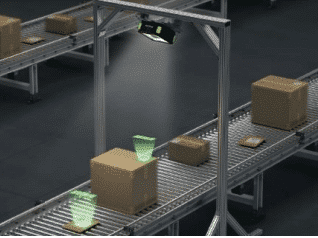

An automated sorting system streamlines the separation and distribution of products into different routes and packaging lines within a conveyor belt system. It can also dispense directly into containers, bags, or trays. Thanks to the continuous product flow through the system, high levels of efficiency and performance are achieved.

Sorting conveyor

A sorting conveyor system can classify products and packages based on barcode data, RFID, color, size, or image recognition using a camera system. Its operation is managed through various mechanisms, such as diverter arms, side belts, air blowers, switch roller sorters, and plastic belt conveyors with integrated rollers.

High-demand industries, such as retail/e-fulfillment, warehouses, and distribution centers, can greatly benefit from these systems by enhancing efficiency and operational capacity. Their compact design allows for increased capacity without requiring additional floor space.

We work closely with our clients to understand their processes and design customized solutions that meet their current and future needs.

Package Sorting System

Our sorting system enables the classification and handling of a wide range of products of various sizes and shapes, including packages, boxes, cases, cartons, shrink-wrapped containers, books, mail, polyethylene bags, and letter-sized items. These conveyors are designed to minimize product damage, ensure continuous flow, reduce accumulation, and optimize spacing between items.

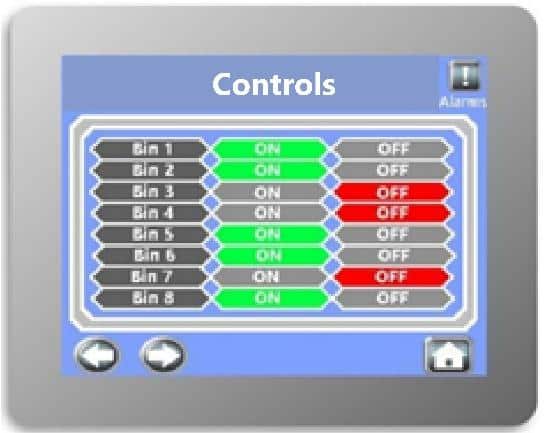

The system features an intuitive touch interface that simplifies operation. It displays clear information and help screens, along with error messages that speed up problem identification and resolution.

Barcode Reading

To ensure reliable and efficient reading, a high-spec barcode reader such as the Keyence SR-5000 can be integrated. This device offers an ultra-wide field of view, great reading depth, and high processing speeds.

By using a camera-based sorting system, products do not require a specific orientation to be read, reducing equipment costs and improving efficiency.

Remote access to the PLC and barcode system allows for minor software adjustments and provides on-site technical support quickly and efficiently. Additionally, we offer mechanical and electrical installation services along with comprehensive training for system operation. We also provide maintenance contracts and essential spare parts to ensure optimal system performance.

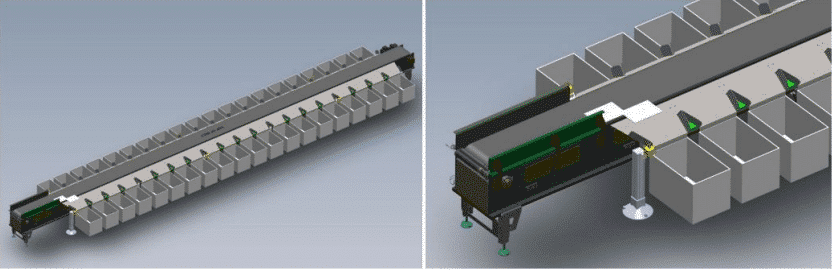

Plastic Belt Sorting Conveyor with Integral Roller

OSG incorporates the Intralox ARB™ S7000 sorter, enabling bidirectional sorting with a throughput of up to 500 products per minute.

This system can accurately and efficiently divert items to the left or right of the main belt, ensuring smooth and safe operation.

Each product is scanned at the beginning of the line, diverted from the central belt, and directed to its designated container. Thanks to a continuous flow, multiple products can be processed simultaneously on the conveyor belt. From an initial conceptual design, a 3D CAD model is developed for subsequent construction, installation, and software integration.

The sorting system software processes the information from the barcode reader and controls the operation of the S7000 sorter. Communication with the warehouse management system (WMS) is carried out via TCP/IP, allowing barcode data reception and managing the sorting and routing of products to their correct destination.

Touchscreen HMI

The system includes a touchscreen HMI that allows operators to easily enable and disable container locations. Active positions are highlighted in green, while inactive ones appear in red.

Mimic screens provide a graphical representation of the sorting line, displaying the real-time status of each segment and highlighting potential blockages for quick problem identification. Additionally, they allow operators to adjust system settings, with password protection ensuring access is restricted to authorized personnel only.

Contact Us

If you are interested in optimizing your sorting process, contact us to discuss your project. We will help you design and specify the most suitable conveyor sorting system for your needs.