Fully automatic stacking and destacking

Insert or remove the pallets with a manual pallet truck, an electric stacker, or a forklift. PALOMAT® Greenline detects the pallets through photo sensors and automatically stacks or destacks them one by one at ground level.

When selecting destacking, a stack of up to 15 to 25 pallets will be inserted into the PALOMAT®, after which the pallets will be fully automatically destacked one by one. When selecting stacking, the pallets are inserted one by one and are fully automatically stacked. The entire stack can then be removed. The PALOMAT® Greenline is only operated manually via a touchscreen panel to switch between stacking and destacking.

The PALOMAT® can handle all 4-way pallets, whether made of wood, plastic, or metal, regardless of their length, width, or height. We can customize the PALOMAT® to fit exactly the size and type of pallets you use.

Benefits

Benefits of automating pallet supply include:

Safety system

The PALOMAT® Greenline features the CE mark, ensuring compliance with European regulations regarding safety, hygiene, and environmental protection.

Technical features

| Item no. | Machine dimensions Length x Width x Height (mm) |

Pallet size Length x Width x Height (mm) | Lifting capacity (kg) | No. of pallets |

|---|---|---|---|---|

| 152001* | 1520x1340x955/2350 | 1200x800x144 | 500 | 15 |

| 152002* | 1520x1540x955/2350 | 1200x1000x150 | 500 | 15 |

| 152101** | 1520x1340x3750 | 1200x800x144 | 700 | 25 |

| 152102** | 1520x1540x3750 | 1200x1000x150 | 700 | 25 |

PALOMAT® Greenline

The Palomat is loaded using a pallet truck or forklift. All handling is always done at ground level. The Palomat detects the pallet through a photosensor.

Includes:

Optional

Door for safety frame for 15 pallets

The door is part of the safety frame and is installed for added security. The PALOMAT® can only be operated with the door closed and locked via a safety switch.

This door covers the right front from the top of the second pallet at floor level to the top of the safety frame. The door is the same type as the one in the 25 pallet storage.

Maximum indicator

A Sick sensor that detects when the pallet stack is full.

If the PALOMAT® needs to stop at 15 pallets, a maximum indicator can be installed on the safety frame or on a bar.

When the maximum indicator is triggered, for example, at 15 pallets, the stack is automatically placed on the ground and ready to be collected. This operation can also be done manually from the touchscreen.

Beacon, maximum indicator

A signaling beacon with a three-color LED to assist the user in operating the machine. The signaling tower includes Sick sensors that detect when the pallet stack is full or empty. If the Palomat needs to stop, for example, at 15 pallets, the signaling tower with the maximum indicator can be mounted on the safety frame or on a bar. When activated, the light turns blue, and the stack is automatically placed on the ground.

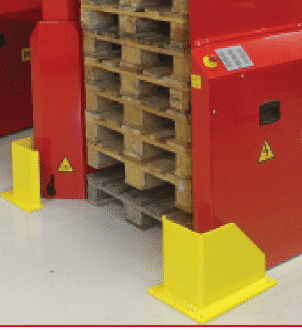

Forklift protection (H:300 x W:310)

Item number: 160533

The 10 mm steel forklift protection (H:300 x W:310) is offered as an additional protection for the PALOMAT®. It is supplied in pairs and is bolted to the floor in front of the PALOMAT®. This option is especially used in environments where forklifts are operated.