Collaborative robots: the key to logistics automation

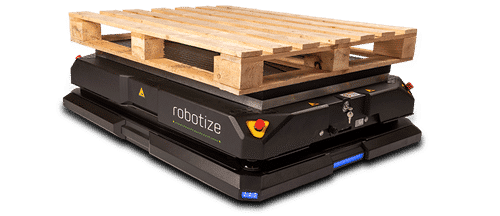

At OSG Group, in collaboration with Robotize, we offer advanced collaborative robots solutions to automate logistics processes. Our line of autonomous mobile robots (AMRs) GoPal is designed to optimize the internal transport of palletized goods, significantly improving operational efficiency, safety, and productivity in industrial environments.

With cutting-edge technology, these collaborative robotics systems adapt to different sectors and layouts, from distribution warehouses to complex production lines. These solutions not only reduce operational costs but also minimize waiting time and improve safety within facilities.

GoPal collaborative robot models

Robotize’s GoPal autonomous mobile robot (AMR) line offers a solution adaptable to different types of loads and logistical needs. These robots are designed to work in collaboration with operators, ensuring a constant flow of materials and increasing efficiency in internal transport.

A wide range of accessories that ensure the functionality of the system with GoControl management software as its main stronghold.

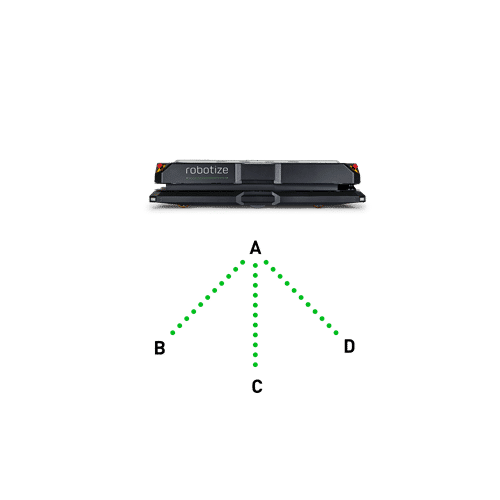

Types of jobs in collaborative robots: simple delivery, complex delivery, and production support

In the logistics automation process, it is essential to differentiate the various transport configurations that collaborative robots can perform. Depending on the complexity of the operations and the production needs, jobs are classified into three main categories: simple delivery, complex delivery, and production support.

Simple delivery

This type of job is ideal for repetitive and linear logistical tasks, where the robot transports a pallet from point A to point B without interruptions or detours.

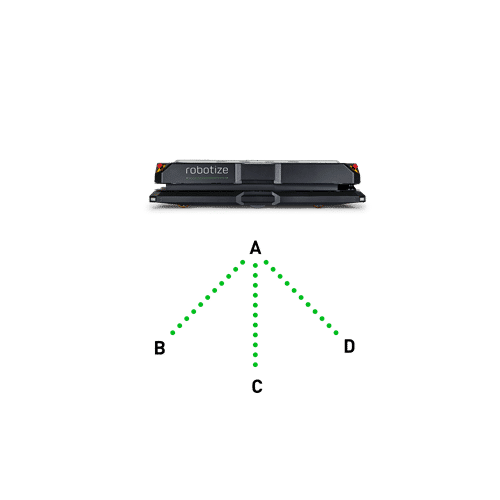

Complex delivery

Complex deliveries involve multiple intermediate stops, detours, or different delivery conditions at each destination. This type of operation requires advanced planning and is managed through the GoControl FMS control system.

Production support

This job is a combination of automated transport and synchronization with production processes in real-time. Collaborative robots supply materials to production lines continuously and automatically, avoiding interruptions and improving operational efficiency.

With these approaches, Robotize’s collaborative robots with OSG Group become an essential tool for maintaining the flow of logistics and production processes in complex industrial facilities.

Benefits of collaborative robots in logistics

The implementation of collaborative robots in internal logistics offers multiple advantages that enhance production processes and safety within facilities. With Robotize’s GoPal line, companies can optimize their workflows and reduce operational costs, increasing their competitiveness in the market.

Accessories and stations for full automation

To maximize the performance and adaptability of GoPal collaborative robots, Robotize offers a wide range of accessories and stations that easily integrate into the logistics processes of any industry. These components allow for the customization of automated transport solutions, enhancing operational efficiency and control over operations.

Pallet station

Pallet station expansion

Charging station

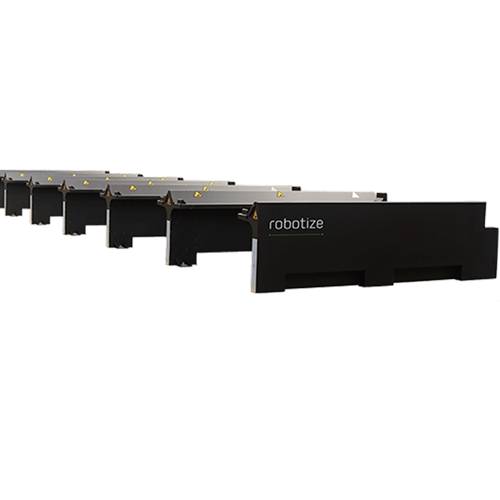

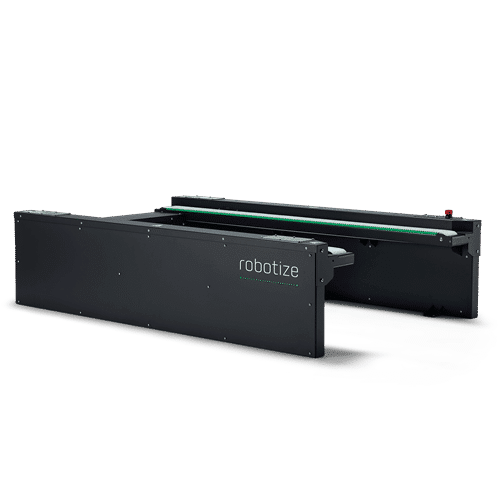

Conveyor stations (E and EW)

Lifting station

Signal beacon

To maximize the performance and adaptability of GoPal collaborative robots, Robotize offers a wide range of accessories and stations that easily integrate into the logistics processes of any industry. These components allow for the customization of automated transport solutions, enhancing operational efficiency and control over operations.

GoControl FMS

GoControl GoPal by Robotize FMS is the central management system that coordinates all components of Robotize’s collaborative robotics solution. This software is the core of automated operations, enabling real-time monitoring, control, and optimization of GoPal robots, stations, and associated accessories.

With GoControl FMS, companies achieve integrated, secure, and efficient management of all their automated logistics processes. This system not only enhances productivity but also provides a strategic view of operational performance, facilitating informed decision-making.

Optimize your logistics with collaborative robots

Discover how OSG Group can transform your internal processes with advanced automated transport solutions. Increase efficiency, enhance safety, and reduce costs with our collaborative robots and customized accessories.

Contact us today to request a demo or more information on how to integrate collaborative robots into your business.