KS line from Alusic: Lightweight bridge solutions for the industry

The KS line from Alusic redefines mobility and support solutions in industrial environments through advanced linear systems, rolling rails, and carts.

Designed to facilitate the implementation of sliding structures, this line perfectly adapts to applications requiring efficient and safe handling of tools and equipment in the workspace.

Linear systems and rolling rails: KS line from Alusic

The KS line from Alusic integrates two essential components for creating movement and transport solutions in industrial environments: Linear Systems and Rolling Rails. Both are designed to efficiently adapt to load requirements and space configuration.

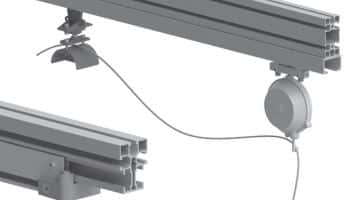

Linear Systems

Alusic’s linear systems provide a quick and functional way to implement sliding solutions. These systems are ideal for mobile workstations that facilitate the transportation and support of tools and instruments necessary for production. Based on extruded aluminum profiles and plastic or aluminum carts, these systems offer versatility and durability in industrial applications.

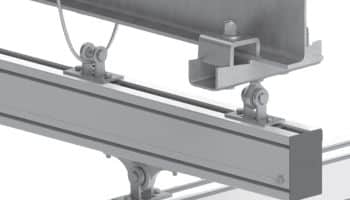

Roller Tracks

Roller tracks are part of crane systems and are designed to support significant loads with simple installation and efficient operation. They allow for the smooth movement of loads along a defined path, optimizing space and improving internal logistics. The choice of the appropriate system will depend on the magnitude of the load and the distance between supports, elements that Alusic specifies clearly to ensure proper sizing by the customer.

Technical features of the KS LINE

Functional and versatile components

Proven capacity and durability

The components of the KS Line are designed to provide quick and functional solutions for creating sliding systems, such as mobile workstations and transportation systems. These components allow for easy attachment and mobility of the tools and instruments necessary in the production activity, ensuring a more efficient and adaptable work environment.

The special carts in the KS Line, made from polyamide and steel, have been tested to withstand over 300 km of continuous use, with a load capacity of up to 75 kg. This guarantees a durable and robust solution for various industrial applications.

Crane systems and compatible profiles

Customized solutions

Incorporating extruded aluminum profiles EN AW 6063 T6 with a surface treatment of class 20 µm and compliance with UNI-EN 12020-2 standards, the KS Line offers high compatibility with other profiles and accessories in the 45 series with an 8-slot. This facilitates the integration and expansion of existing systems with options such as column and wall-mounted flag cranes, which are available with fixed and articulated suspension options, as well as double and single trolleys.

With five different profile matrices, ranging from 90×60 to 180×90, and pneumatic connections for compressed air, the KS Line allows for custom configurations that meet the specific needs of each industrial application, providing superior flexibility and functionality.

Technical features of the KS LINE

The components of the KS Line are designed to provide quick and functional solutions for creating sliding systems, such as mobile workstations and transportation systems. These components allow for easy attachment and mobility of the tools and instruments necessary in the production activity, ensuring a more efficient and adaptable work environment.

The special carts in the KS Line, made from polyamide and steel, have been tested to withstand over 300 km of continuous use, with a load capacity of up to 75 kg. This guarantees a durable and robust solution for various industrial applications.

Incorporating extruded aluminum profiles EN AW 6063 T6 with a surface treatment of class 20 µm and compliance with UNI-EN 12020-2 standards, the KS Line offers high compatibility with other profiles and accessories in the 45 series with an 8-slot. This facilitates the integration and expansion of existing systems with options such as column and wall-mounted flag cranes, which are available with fixed and articulated suspension options, as well as double and single trolleys.

With five different profile matrices, ranging from 90×60 to 180×90, and pneumatic connections for compressed air, the KS Line allows for custom configurations that meet the specific needs of each industrial application, providing superior flexibility and functionality.

Explore the KS LINE from Alusic for industrial mobility solutions

Maximize the efficiency and adaptability of your workspace with Alusic’s linear systems. To discover how the KS LINE can transform your industrial operation, contact Sitalu today and take advantage of our personalized solutions and expert support.